The Ford 3000 tractor, a stalwart of agricultural history, owes much of its functionality to its robust hydraulic system. This guide delves into the intricacies of this system, blending historical context with practical, actionable advice for maintenance and troubleshooting. Understanding the Ford 3000's hydraulics is not just about fixing leaks; it's about appreciating a crucial element of agricultural mechanization and improving its efficiency. For even more detailed information, check out this helpful Ford 3000 resource.

Understanding the Ford 3000 Hydraulic System: A Historical Perspective

The Ford 3000, introduced in the mid-20th century, played a significant role in the mechanization of agriculture. Its hydraulic system, while simpler than modern counterparts, was a critical advancement, allowing for efficient operation of implements like plows, harrows, and loaders. This system's reliability and relative ease of maintenance contributed to its widespread adoption by farmers worldwide. But how did this innovation impact sustainable agriculture? Did it pave the way for the sustainable techniques we use today? These are some of the questions we will address.

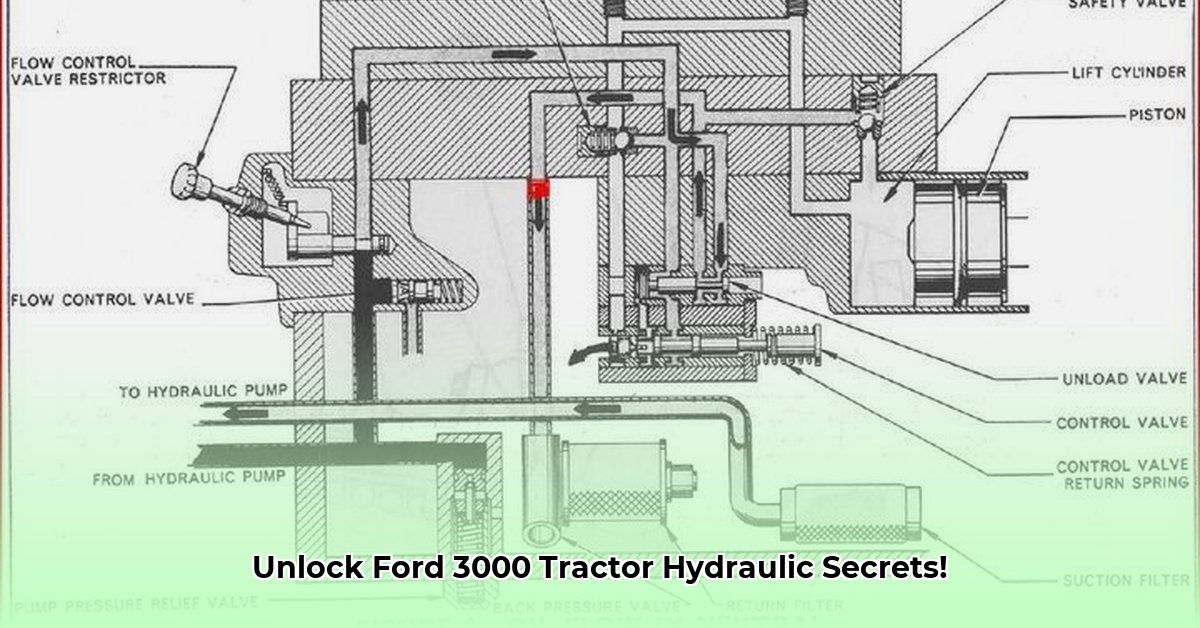

A Visual Guide: The Ford 3000 Hydraulic Diagram

A clear hydraulic diagram is indispensable for understanding the Ford 3000's system. (Insert a clear, labeled hydraulic diagram of the Ford 3000 here. Multiple diagrams showing different aspects of the system, such as the three-point hitch and steering system, would be beneficial.) This diagram visually represents the flow of hydraulic fluid, showing how pressure is generated, controlled, and used to perform various tasks. Familiarizing yourself with this diagram is the first step towards effective troubleshooting and maintenance.

Key Components of the Ford 3000 Hydraulic System

The Ford 3000's hydraulic system relies on several interconnected components working in concert. Let's examine each:

Hydraulic Pump: This component generates the pressure needed to move the hydraulic fluid. Think of it as the heart of the system, constantly circulating fluid throughout the system. A malfunctioning pump severely hinders operation.

Control Valves: These valves direct the flow of hydraulic fluid, similar to traffic signals controlling the flow of cars. They ensure that fluid reaches the correct actuators at the right moment and with the appropriate pressure.

Hydraulic Cylinders: These convert hydraulic pressure into linear motion, powering the movement of implements and other parts. They are the "muscles" of the system, responsible for lifting, lowering, and moving machinery.

Hydraulic Reservoir: This tank stores the hydraulic fluid, ensuring a continuous supply of fluid for the pump. Maintaining the correct fluid level is crucial for smooth and reliable operation.

Filters: These remove contaminants from the hydraulic fluid, preventing them from damaging sensitive system components. Regular filter replacement is essential for system longevity.

Troubleshooting Common Hydraulic Problems

While the Ford 3000's hydraulic system is relatively robust, problems can arise. Here are some common issues and basic troubleshooting steps:

Implement Won't Lift: Check the fluid level in the reservoir. Low fluid levels necessitate immediate replenishment. If the level is correct, investigate the pump's functionality. A faulty pump requires professional attention.

Sluggish Response: Slow or delayed responses could indicate a leak, often detectable as fluid drips or moisture around the hoses and fittings. Inspect all hoses and connections. A blocked filter is another potential issue, requiring filter replacement.

Intermittent Operation: If the system works erratically, air in the system might be the culprit. Bleeding the system, which involves removing air bubbles, may resolve the issue. (Consult your owner's manual for specific instructions.)

Safety Note: Always disconnect the power source before performing any maintenance or troubleshooting on the hydraulic system.

Essential Maintenance for Optimal Performance

Preventive maintenance is key to ensuring the longevity and efficiency of your Ford 3000's hydraulic system. This involves:

Regular Fluid Level Checks: Monitor the hydraulic fluid level regularly, checking for leaks and topping off as needed.

Filter Replacements: Replace hydraulic filters according to the manufacturer's recommendation. This step keeps the hydraulic fluid clean, preventing damage to components.

Routine Inspections: Regularly inspect all hoses, connections, and cylinders for leaks or damage, addressing minor issues promptly.

The Ford 3000's Hydraulic System and Sustainable Agriculture

The Ford 3000, though a product of its time, played a vital role in promoting sustainable agriculture by reducing labor needs and increasing efficiency in various farming operations. While modern tractors offer improved fuel efficiency and more sophisticated hydraulic systems, the Ford 3000's contribution to mechanization should not be overlooked. It served as a stepping stone to advanced agricultural technologies.

Key Takeaways:

- The Ford 3000's hydraulic system is relatively straightforward to understand and maintain.

- Regular maintenance prevents costly repairs and maximizes the tractor's operational lifespan.

- Understanding the hydraulic system's basic principles is essential for efficient and sustainable farming practices.

This guide provides a foundation for understanding and maintaining the Ford 3000's hydraulic system. Remember to consult your owner's manual for specific details and recommendations.